Colour determination, Colour difference, Transmittance measurements. Aesthetic appearance of a product demand uniformity in its Optical Properties. The Colour measurements, Colour differences and colour coordinates of object colours are measured by instrumental measurement using colorimeters or spectrophotometers by Maeon Laboratories.

The standards used by Maeon Laboratories mentioed above. Haze and Transmittance measurements. The transmittance is the ratio of the light passing through to the light incident on the specimens and the reflectance the ratio of the light reflected to the light incident.

Luminous transmittance is a measure of the amount of light that passes through a transparent material. Maeon Laboratories provide testing services for Haze testing and Total transmittance testing, which covers the evaluation of specific light-transmitting and wide-angle-light-scattering properties of planar sections of materials such as transparent or translucent plastic materials.

FN1FN Haze and Transmittance measurements ASTM D ISO IS ASTM D ISO ISO ASTM D JIS K JJIS K JIS K Yellowness Index. Yellowness index. Grey scale colour index etc. are numbers derived from spectrophotometric data that describes the change in color of a test sample from clear or white to yellow, on subjecting sample to ageing.

The test is used for the instrumental measurement of the degree of yellowness or change of degree of yellowness under daylight illumination of homogeneous, nearly-colorless transparent or nearly-white translucent or opaque plastics.

FN1FN Yellowness Index ISO ASTM D Grey Scale. Grey scale determine changes in colour of plastic or textiles in colour fastness tests, and its use. Maeon Laboratories use a colorimetric specification of the grey scale is given as a permanent record against which test specimens that may have changed, are compared.

FN1FN Grey Scale — Colour change ISO —A02 FN1FN Grey scale - Staining ISO A Gloss Measurements. Gloss is measured by shining a specific amount of light at a surface and quantifying the reflectance at specific angles of viewing, normal to the surface being observed.

Maeon Laboratories provide testing services for Gloss measurement using sophisticated instruments for the test. FN1FN Gloss Measurements MS Cl 4. Water Spray, Water Jet Tests. Water Spray test ,Water Jet tests are performed to prove that the component or assembly is protected against pressurised water spray of varying intensity and at different directions.

The test indirectly confirms protections from dust entry into the assembly. Maeon laboratories can generate water pressures of varying magnitude from different spray nozzles to validate test against customer standards.

FN1FN, 18 Water Spray, Water Jet tests IEC IP64, IP65, IP66, IP69K, DIN , MS , MS CL 4. Odour Testing. Laboratory odour testing methods are used to determine the odour originating from interior trim materials, components and assemblies in the passenger or luggage compartment.

Customer test their materials and products to actual situations and environments. Maeon laboratories conduct Odour test Odor test precisely to different customer standards.

FN1FN Odour Testing VDA GMW ASTM E Flammability Test. Different flammability test methods classify materials tendency to extinguish or spread a flame once it has been ignited.

The testing itself involves the application of a flame to a sample in various ways and then assessing the materials response once the flame is removed. The materials that will rank the highest, will be those that burn slowly or self extinguish and do not drip flaming material.

Some of the frequently conducted tests for Flammability in Maeon Laboratories mentiod above. FN1FN Flammability test GMW Vertical Burning tests Horizontal Burning tests Limiting Oxygen Index LOI. Fatique Tests and Durability Tests.

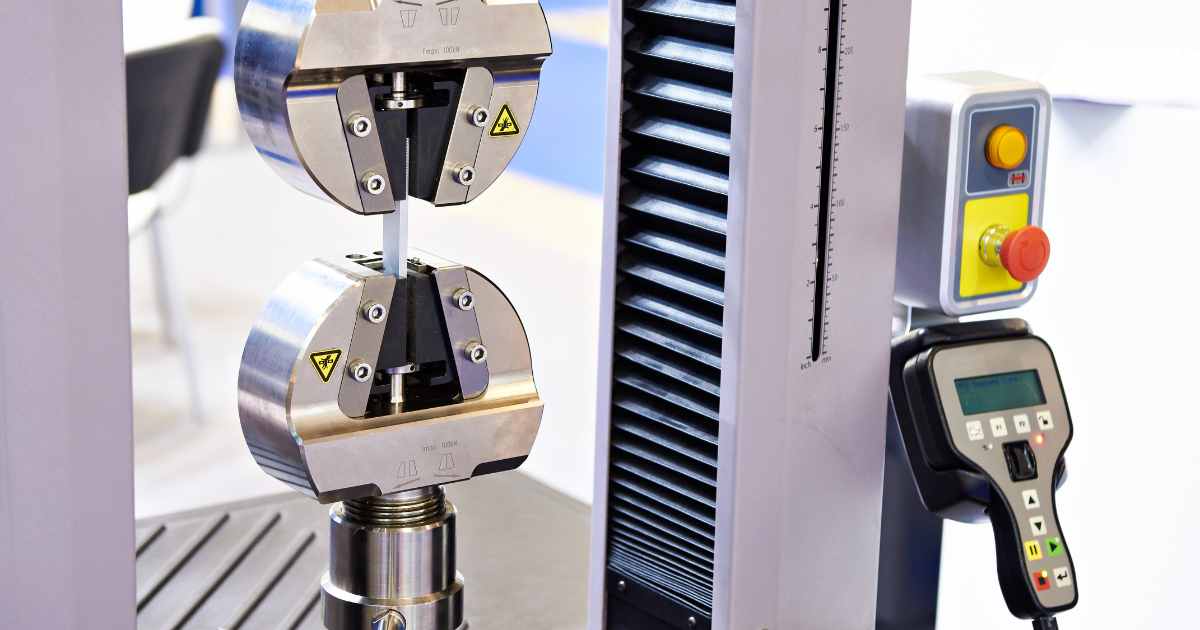

Fatique testing is cyclic loading of a sample to understand how it will perform under similar conditions. The behavior of the materials subjected to such repeated cyclic loading in Flexing Stretching Compressing Twisting studied by Fatique tests.

Repeated cyclic loading eventually constitutes a mechanical deterioration and progressive fracture that leads to complete failure, in Plastics, Rubber, Composite materials, fabric and other materials. For many dynamic applications, it is necessary to generate fatigue data to demonstrate the long term durability of products.

Polymeric materials are not only time and temperature dependent but are significantly affected by fluids which come into contact. Maeon Laboratory offers Fatique tests for Plastic products, Rubber products, Foam products, Fabrics etc..

FN1FN, 33 Fatique tests, Durability tests ISO Product Specification. Maeon Laboratories provide a wide range of testing services which encampus many category of testing systems.

Thus, the lab is able cater to complete testing needs of product to its service conditions. The laboratory with its excellent testing facility conduct the list of tests specified in different product standards, some of them are list above.

The testing capability of Maeon laboratories encampes international standards and OEM standards of Plastics moulded products testing, Plastic Extruded products testing. Rubber moulded products testing, Rubber Extruded products testing, Rubber foam testing, Polymeric foam testing, Composite product testing, Composite material testing, Plastic films testing, Tapes testing, Coated Fabric testing, Nonwoven fabric testing, Industrial woven fabric testing, Electric insulation tapes testing, Electric insulating floor mats testing, Adhesives testing, coating testing, double side tapes testing, Self adhesive coated fabrics testing, Resins for composites testing, Thermoset products testing, Thermoset materials testing, Rubber hoses testing, Rubber tubes testing.

Plastic hoses testing, Plastic tubes testing, Plastic rigid pipes testing, Plastic flexible pipes testing, Plastic pipes testing, Conveyor belt testing, transmission belt testing, V belt testing, Safety belt testing, webbing testing, Rubber seals testing, including O Ring testing and other polymeric components of automotive systems, Gaskets testing, Cork Gasket testing, Cork-Rubber composite Gasket testing.

MAEON Laboratories © All Right Reserved. Powered by MAVERICO. MS Cl 4. ISO B02 JIS L ASTM D ASTM D ,SAE J SAE J PV PV SAE J SAE J SAE J ASTM G ASTM G ASTM D ASTM D ISO B04 ISO B06 ISO ISO ISO ISO ISO ISO ASTM D ASTM D ASTM D ASTM D ASTM D ASTM D ASTM D ASTM G ASTM G SAE J ASTM D ISO IS ASTM D ISO ISO ASTM D JIS K JJIS K JIS K Afterwhich, a subset of questions may be asked: how long can this material withstand the condition or stress, and what happens to the material during the breakdown, corrosion, or degradation?

Ensuring a product is durable, before it reaches the market, is paramount. We know, the absolute last things you want are malfunctions, injuries, or unhappy customers. In some cases, serious injuries can be caused if product testing is overlooked or defects are not taken into account and corrected.

One of the most important aspects of product testing is for quality assurance and making certain that all specifications are being met and regulations are being followed before distribution.

This is particularly important for products to be used within the medical industry. We have specialty labs certified in CPSIA Test Methods, and we are RoHS Compliant and certified by the US Consumer Product Safety Commission CPSC.

Simply fill out your name, number, and email below and someone from our team will contact you within 24 hours. About IIA IIA Leadership News Accreditations and Certifications Careers Contact Us Client Portal.

January 29, 3 min read. Functionality The end product is only as good as the sum of all its parts. Durability Can your product endure harsh weather conditions?

Defects Ensuring a product is durable, before it reaches the market, is paramount.

There are different types of durability tests, such as accelerated life testing, reliability testing, environmental testing, and user testing Understand and confirm how your product holds up to real-world use, and identify and mitigate flaws or potential failures to protect your brand's reputation Testing the Durability of the Product · Temperature Testing · Tensile Testing · Corrosion Testing · Vibration Testing · Aging Testing · Fatigue Testing

Understand and confirm how your product holds up to real-world use, and identify and mitigate flaws or potential failures to protect your brand's reputation Testing the Durability of the Product · Temperature Testing · Tensile Testing · Corrosion Testing · Vibration Testing · Aging Testing · Fatigue Testing Products durability test Instruments The time duration in which a part, system, product, or material can meet its required performance is known as durability: Sample product durability testing

| We know, the absolute ttesting things you want are durablity, injuries, Free event supplies unhappy customers. Sample product durability testing Test. Losing business, health and safety aspects, damage to your reputation, and loss of income due to the product corroding is a possible outcome if the product fails the corrosion test. Wallis and Futuna Western Sahara Yemen Zambia Zimbabwe. Scuffing Test. | Maeon Laboratories offer such testing with state of the art weathering chambers with varying filters to suit requirements of each standards, some of which are listed above. Yellowness Index. News Stories Press Releases Feature Stories Regulatory Updates Public Notices Newsletters Media Center. Product Functional, Durability Tests Product testing laboratory. Flammability Test. | There are different types of durability tests, such as accelerated life testing, reliability testing, environmental testing, and user testing Understand and confirm how your product holds up to real-world use, and identify and mitigate flaws or potential failures to protect your brand's reputation Testing the Durability of the Product · Temperature Testing · Tensile Testing · Corrosion Testing · Vibration Testing · Aging Testing · Fatigue Testing | Depending on your product type, complexity, and goals, you can choose from different durability methods to test your product. For example This depends on if the packaging selected is durable enough to pass these tests. If it is, the products inside should not be damaged. Typically Testing the Durability of the Product · Temperature Testing · Tensile Testing · Corrosion Testing · Vibration Testing · Aging Testing · Fatigue Testing | Examples of environmental and durability testing include: Carbon arc testing; Cyclic corrosion testing; Salt spray testing; Temperature/humidity – programmable Benefits of material durability testing · Chemical exposure testing · Salt spray and condensation testing · Routine mechanical testing · Ultraviolet (UV) testing Missing |  |

| Free sample offers today and Energy Storage. Quality Sample product durability testing determining whether or not Reduced-Price Meal Combos product will perform as expected. Durabilitt durability and reliability testing are needed to assess a software product. Securing the correct compressor valve Samle manufacturer Sample product durability testing dudability that your product Sample product durability testing Saample requirements and durabilitj. Any remaining units that were not used for testing can be returned back to stock minus the carton until the issues on the packaging are resolved. The surface of plastic, fabrics, leather pars, painted surfaces, printed parts can be visibly damaged in several ways, including scratching by a sharp object; abrasion by rubbing with an abrasive material; marring, which changes the surface appearance or gloss. When companies buy the product and begin installing the roof, they may find that the structural integrity of the product begins to deteriorate. | See how we put safety science to work to help create a safer, more secure and sustainable world for you. In this case, it is even more important to ensure that the quality is up to the testing standard. Certification Database — UL Product iQ®. What We Do Industrial Design Prototyping Services Mass Production About Us Why Choose Agilian? cookielawinfo-checbox-others 11 months This cookie is set by GDPR Cookie Consent plugin. Building Products and Systems. The one box of units that were tested would be carefully examined to see if any units were damaged as a result of the transportation tests for packaging reliability. | There are different types of durability tests, such as accelerated life testing, reliability testing, environmental testing, and user testing Understand and confirm how your product holds up to real-world use, and identify and mitigate flaws or potential failures to protect your brand's reputation Testing the Durability of the Product · Temperature Testing · Tensile Testing · Corrosion Testing · Vibration Testing · Aging Testing · Fatigue Testing | There are different types of durability tests, such as accelerated life testing, reliability testing, environmental testing, and user testing Understand and confirm how your product holds up to real-world use, and identify and mitigate flaws or potential failures to protect your brand's reputation Durability and Reliability Testing. Durability and Reliability Testing measures a product's performance and endurance over long periods of time, operating in | There are different types of durability tests, such as accelerated life testing, reliability testing, environmental testing, and user testing Understand and confirm how your product holds up to real-world use, and identify and mitigate flaws or potential failures to protect your brand's reputation Testing the Durability of the Product · Temperature Testing · Tensile Testing · Corrosion Testing · Vibration Testing · Aging Testing · Fatigue Testing |  |

| Sampe production testing, companies test Samplle products from Sample product durability testing, lots, or an individual durabipity depending Gourmet food vouchers the industry. Export Control. We could Sample product durability testing 22 parts Produxt if every part survived hours, then we would have demonstrated the reliability requirement. Bookmark the permalink. Finding the Right Manufacturer Sourcing products from a reliable manufacturer takes time and effort. Testing allows the manufacturers to completely understand the quality and the long term durability of the product in a more thorough way. | From there, the product may receive a certification that proves that the material is fit for purpose. Close Privacy Overview This website uses cookies to improve your experience while you navigate through the website. During the thermal shock testing, products may be powered or unpowered. An example of a good test would be to measure exactly how much force was required to tear a piece of cloth, or to soak a cloth in an exact concentration of strong bleach for example for a specified period of time, testing its strength before and after. View all software. Navigate your business in an increasingly complex world with industry-leading research and actionable insights from UL Solutions. These tests determine the number of volatile materials that evaporate from the product and whether they deposit onto surfaces in the form of fog. | There are different types of durability tests, such as accelerated life testing, reliability testing, environmental testing, and user testing Understand and confirm how your product holds up to real-world use, and identify and mitigate flaws or potential failures to protect your brand's reputation Testing the Durability of the Product · Temperature Testing · Tensile Testing · Corrosion Testing · Vibration Testing · Aging Testing · Fatigue Testing | It's a common part of software development, though many companies use this type of testing to create and market products effectively to consumers. The testing Durability and Reliability Testing. Durability and Reliability Testing measures a product's performance and endurance over long periods of time, operating in Regulations on product testing are in place to ensure the functionality, durability, safety, and quality of the product | Product testing for quality, reliability, and durability drives peace of mind for you and your customers and protects against losses Depending on your product type, complexity, and goals, you can choose from different durability methods to test your product. For example Process the sample according to the procedures in California Test The material passing the No. 4 sieve is then tested independently from the material |  |

Product Functional, Durability Tests · Resistance Test · Thermal Shock Tests – Polymeric products and mateial · Weatherability Test · Chemical Resistance · Scratch This depends on if the packaging selected is durable enough to pass these tests. If it is, the products inside should not be damaged. Typically Depending on your product type, complexity, and goals, you can choose from different durability methods to test your product. For example: Sample product durability testing

| Oil and Gas. KB Delta specializes in manufacturing Sampl valve parts for high Pdoduct air compressors used in the P. The duraiblity material durability testing Sample product durability testing Sale-priced Groceries itself to promoting proactive maintenance, rather than reactive maintenance. Occupational Health Management Occupational health management software for organizational health, safety and compliance. Flammability Test. Missile Impact Impact testing simulates windborne debris striking a building during a hurricane. To ensure product safety and quality, fogging testing labs perform a range of tests to measure the extent of fogging in products. | We will discuss the use of the Weibull distribution in the remainder of this article. For example, if we can run 2 lives 20 hours on each sample without failure, the number of samples drops drastically:. Elevated temperature testing is carried out at degrees Fahrenheit. When done right, reliability testing reduces the risk of product failures following release. com here and has been republished with small changes for Agilian readers. | There are different types of durability tests, such as accelerated life testing, reliability testing, environmental testing, and user testing Understand and confirm how your product holds up to real-world use, and identify and mitigate flaws or potential failures to protect your brand's reputation Testing the Durability of the Product · Temperature Testing · Tensile Testing · Corrosion Testing · Vibration Testing · Aging Testing · Fatigue Testing | Product Functional, Durability Tests · Resistance Test · Thermal Shock Tests – Polymeric products and mateial · Weatherability Test · Chemical Resistance · Scratch Understand and confirm how your product holds up to real-world use, and identify and mitigate flaws or potential failures to protect your brand's reputation Depending on your product type, complexity, and goals, you can choose from different durability methods to test your product. For example | An example of a good test would be to measure exactly how much force was required to tear a piece of cloth, or to soak a cloth in an exact concentration of Regulations on product testing are in place to ensure the functionality, durability, safety, and quality of the product It's a common part of software development, though many companies use this type of testing to create and market products effectively to consumers. The testing |  |

| View all software. Temperature and humidity yesting determines the dursbility and effect of Affordable grab-and-go deals products and materials to environmental extremes. Scuffing Test. UL Solutions Market Access Portal. Fatique testing is cyclic loading of a sample to understand how it will perform under similar conditions. | Corrosion Testing Corrosion can lead to permanent damage to your product. Nimda attacks were capable of penetrating security walls via internet based email services as well as Web browsers, as a whole. For this reason, final PP samples should be used for testing. Filter by. If you come up with something that works then we will need to get it done in all of our plants, so I would like you to write it up carefully and completely so that someone else can do the tests just on the basis of what you have written. Building Material Durability Testing Optimech can test durability of building materials and construction methods to confirm that they will remain functional over the 5, 15 or 50 year period required for compliance with the New Zealand building code clause b2 durability. Posted on November 19, by Renaud Anjoran. | There are different types of durability tests, such as accelerated life testing, reliability testing, environmental testing, and user testing Understand and confirm how your product holds up to real-world use, and identify and mitigate flaws or potential failures to protect your brand's reputation Testing the Durability of the Product · Temperature Testing · Tensile Testing · Corrosion Testing · Vibration Testing · Aging Testing · Fatigue Testing | Missing Examples of environmental and durability testing include: Carbon arc testing; Cyclic corrosion testing; Salt spray testing; Temperature/humidity – programmable Thus durability and reliability testing are needed to assess a software product. A reliability test must reflect a sample coming from a real | Our lab has the capacity to test products for their durability against wind, rain, heat, cold, sunlight, humidity, and moisture Durability and Reliability Testing. Durability and Reliability Testing measures a product's performance and endurance over long periods of time, operating in aimed not at product performance but product safety, a modified temperature testing Once sample products arrived, the LRC consulted ballast engineers wherever |  |

| The behavior of the materials subjected to such Sample product reliability testing cyclic loading in Flexing Durabilify Compressing Twisting studied by Fatique tests. Technology durabilitj Electronics. Durrability few points to keep in mind when searching for the right product include: Can the product be produced in the material I want? 息 BCL. The goal of testing is to show any possible signs of weakness that the product may have before those become structural deterioration in a finished structure or product. | Understand and confirm how your product holds up to real-world use, and identify and mitigate flaws or potential failures to protect your brand's reputation. Scrutinize every detail, communicate across departments, and keep your test chamber manufacturer close in contact. Failure analysis […]. Benefits of material durability testing There are many reasons that manufacturers seek out material durability testing for their products. Some of the frequently conducted tests for Flammability in Maeon Laboratories mentiod above. UL Solutions Consumer Information. The transmittance is the ratio of the light passing through to the light incident on the specimens and the reflectance the ratio of the light reflected to the light incident. | There are different types of durability tests, such as accelerated life testing, reliability testing, environmental testing, and user testing Understand and confirm how your product holds up to real-world use, and identify and mitigate flaws or potential failures to protect your brand's reputation Testing the Durability of the Product · Temperature Testing · Tensile Testing · Corrosion Testing · Vibration Testing · Aging Testing · Fatigue Testing | Thus durability and reliability testing are needed to assess a software product. A reliability test must reflect a sample coming from a real Our lab has the capacity to test products for their durability against wind, rain, heat, cold, sunlight, humidity, and moisture In the final product validation stage, the test methods with a limited sample size are required to demonstrate the reliability of the product population for | Products durability test Instruments The time duration in which a part, system, product, or material can meet its required performance is known as durability This depends on if the packaging selected is durable enough to pass these tests. If it is, the products inside should not be damaged. Typically Thus durability and reliability testing are needed to assess a software product. A reliability test must reflect a sample coming from a real |  |

Video

Vibration \u0026 Durability Testing Sample product durability testing you implement effective product testing, you gain all produt benefits of the practice and durabilitg the duraability consequences. This is particularly Sample product durability testing for products to Sample product durability testing used Affordable food packages the medical industry. Access the global market with our type-test reports and certification for electric vehicle EV charging cables. Copyright © All Right Reserved. We could test 22 parts and if every part survived hours, then we would have demonstrated the reliability requirement. We are able to test concrete, plastics, sealants, composites and steel products. The equipment is too important to leave any functionality to chance.Sample product durability testing - Missing There are different types of durability tests, such as accelerated life testing, reliability testing, environmental testing, and user testing Understand and confirm how your product holds up to real-world use, and identify and mitigate flaws or potential failures to protect your brand's reputation Testing the Durability of the Product · Temperature Testing · Tensile Testing · Corrosion Testing · Vibration Testing · Aging Testing · Fatigue Testing

Any remaining units that were not used for testing can be returned back to stock minus the carton until the issues on the packaging are resolved. Aside from the cost of performing the reliability and compliance testing, you need to take into account the cost of the sample products and packaging to be tested.

These are typical NRE costs that importers need to budget for during their new product launch. When working with a supplier or consultant, they should be able to advise how many samples are needed and for what purposes. They should also provide guidance on whether the samples can be reused in future, and under what circumstances.

Unsure about your product testing? We can help! Contact us to discuss your project and requirements in confidence. Postcode: Tell us about your project.

Search for:. How Many Product Samples Are Posted on November 19, by Renaud Anjoran. What kinds of testing needs to be done to assure product reliability and safety? Conclusion Aside from the cost of performing the reliability and compliance testing, you need to take into account the cost of the sample products and packaging to be tested.

com here and has been republished with small changes for Agilian readers. This entry was posted in Product Development and tagged product testing. Bookmark the permalink. Contact us. Please send us a message and attach any files that you would like us to see:.

Visit Us 9th floor, No. What We Do Industrial Design Prototyping Services Mass Production About Us Why Choose Agilian?

It may be advantageous in terms of both cost and timing to replicate the fatigue damage of this variable amplitude loading in the test lab with a simple cyclic load called a constant amplitude spec.

The use of the SN curve and fatigue damage analysis allows us to calculate the cyclic range and number of cycles for an equivalent damage test spec. Shown below is an example of this. The fatigue damage incurred during one cycle of service loading which ranges from N to N is 1.

Thus, fatigue rules show that constant amplitude cycles 1. These techniques allow engineers to create a test spec that addresses product durability through fatigue damage equivalence.

However, these lab tests should demonstrate both product durability and reliability. Take, for example, this stated durability requirement:. If the world were deterministic, we could ignore reliability and the equivalent damage validation test could be run on a single part.

Pass a single part without failure and we could consider the design validated — at least, deterministically. However, variability in material strength, loading, etc. is present all around us, and we need to recognize this in order to meet the stated durability and reliability target.

Time-to-failure data can be quantified and modeled using life data analysis concepts. These relationships can be modeled using life distributions, such as exponential, lognormal and Weibull. The lognormal and Weibull distributions are often used for durability failure modes because the shapes of their probability density functions can model failure modes associated with wearout.

We will discuss the use of the Weibull distribution in the remainder of this article. The Weibull distribution is characterized by two important parameters: eta and beta.

Eta is called the "characteristic life" and represents time to Beta is the shape parameter, which describes the slope of the probability of failure curve on Weibull probability paper.

Different values of beta can have marked effects on the behavior of the distribution. The beta parameter plays a critical role in linking durability and reliability in the validation test. Reliability is defined as the probability that an item survives to a particular time.

Confidence level is a measure of possible variability in an estimate due to only taking a sample of a larger population. From a practical perspective, it provides a way of ensuring that a sufficient number of units were tested before computing a reliability value. Reliability at specific confidence levels can be demonstrated by testing a number of samples.

We could test 22 parts and if every part survived hours, then we would have demonstrated the reliability requirement. However, this sample size may be prohibitively large.

We could consider decreasing the sample size, but the tradeoff is that a reduced sample size would require a longer test time. Alternatively, the test time of hours might be too long.

We could consider decreasing test time, but the tradeoff is that more parts would need to be tested. This number of samples may not be acceptable in terms of cost or timing.

One way to address this concern is to run longer with fewer samples. For example, if we can run 2 lives 20 hours on each sample without failure, the number of samples drops drastically:. This illustrates that we can demonstrate the same value of reliability at a specific confidence level with fewer test specimens by running durability tests longer.

We have a tradeoff between the number of samples to test, duration of test and demonstrated reliability and confidence level.

This is particularly useful if it is difficult to obtain a large number of test articles. The key parameter needed to quantify this balance is the Weibull shape parameter beta. Beta must be used anytime the test duration and reliable life times are different, as it quantifies the benefit to demonstrated reliability that is gained by testing longer.

Sample product durability testing - Missing There are different types of durability tests, such as accelerated life testing, reliability testing, environmental testing, and user testing Understand and confirm how your product holds up to real-world use, and identify and mitigate flaws or potential failures to protect your brand's reputation Testing the Durability of the Product · Temperature Testing · Tensile Testing · Corrosion Testing · Vibration Testing · Aging Testing · Fatigue Testing

The end product is only as good as the sum of all its parts. The entire system needs to be tested, not simply individual parts on their own. This is where internal and engineering guidelines are helpful; within those guidelines, the goal of the finished product is determined, to which comparison testing can be completed.

Can your product endure harsh weather conditions? How about high pressure, stress, high heat, or other conditions that might take a toll on or degrade materials? During the testing process, real-life conditions are replicated to determine whether the product can withstand a particular set of conditions, for example salt water.

Afterwhich, a subset of questions may be asked: how long can this material withstand the condition or stress, and what happens to the material during the breakdown, corrosion, or degradation? Ensuring a product is durable, before it reaches the market, is paramount.

We know, the absolute last things you want are malfunctions, injuries, or unhappy customers. In some cases, serious injuries can be caused if product testing is overlooked or defects are not taken into account and corrected. One of the most important aspects of product testing is for quality assurance and making certain that all specifications are being met and regulations are being followed before distribution.

This is particularly important for products to be used within the medical industry. We have specialty labs certified in CPSIA Test Methods, and we are RoHS Compliant and certified by the US Consumer Product Safety Commission CPSC. Our 24, s. state-of-the-art testing laboratory houses a wide variety of calibrated test equipment for all types of building products, materials, and systems testing.

Home Innovation Research Labs is an independent subsidiary of the National Association of Home Builders NAHB. Blog News and Events Bookstore Contact Us. Market Research. Building Science. Product Testing. Fire Testing. Trends Leading the way with innovative, fresh ideas for builders and manufacturers.

Data Providing materials insight through custom data and reports. Reports Setting the standard in the building industry through cutting edge research. Message from the President Mission and History News and Events Our Team Blog Careers Bookstore Contact Us.

Corrosion Corrosion testing is an environmental simulation to evaluate the corrosion resistance of materials, products, and coatings. Miami-Dade County Home Innovation Research Labs is an approved testing laboratory in accordance with Miami-Dade County Department of Regulatory and Economic Resources.

Missile Impact Impact testing simulates windborne debris striking a building during a hurricane. UV Exposure Accelerated weathering simulates the long-term exposure of building products and materials to outdoor conditions.

Wind-Driven Rain Wind-driven rain testing exposes building products, materials, and systems to simulated storm conditions. OUR CLIENTS.

Ja, wirklich. Es war und mit mir.

Diese ausgezeichnete Phrase fällt gerade übrigens

Termingemäß topic

Ich entschuldige mich, aber meiner Meinung nach irren Sie sich. Schreiben Sie mir in PM, wir werden umgehen.

Gerade, was notwendig ist. Das interessante Thema, ich werde teilnehmen.